You are viewing United States

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

Feed Quality Resources for Swine

Fat-Soluble Vitamins: How to Maximize Your Investment

Fat-Soluble Vitamins: How to Maximize Your Investment

Supplementing fat-soluble vitamins, like vitamin A and vitamin E, in the right amounts at the right time is critical for balanced animal nutrition. Unfortunately, these two vitamins tend to be highly susceptible to activity loss in premixes and in feed.

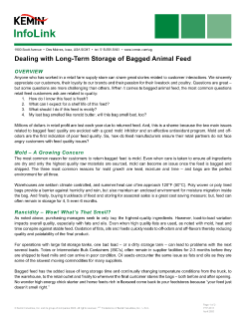

Deoxynivalenol and Zearalenone: Trending Mycotoxins in the 2020/2021 Corn Crop

Deoxynivalenol and Zearalenone: Trending Mycotoxins in the 2020/2021 Corn Crop

During times of rising feed costs, limiting the risks of hidden profit-robbers, like mycotoxins, from eroding livestock and poultry feed efficiency is critical to an operation’s bottom line. Mycotoxins vary year to year due to environmental and storage conditions of grains. To combat the perennial mycotoxin problem, identifying mycotoxin risks in ingredients before manufacturing feeds is key.

Managing Feed Quality is Key for Optimizing Feed Efficiency

Managing Feed Quality is Key for Optimizing Feed Efficiency

With today’s skyrocketing corn, soybean, fat and oil prices, judicious management of feed costs is more critical than ever. The problem is the cost of a feed ingredient may not accurately reflect quality, nutritional value or return on investment. Profit-robbers in feed – molds, mycotoxins, oxidation and more – may be stealing valuable nutrients from feed, thereby reducing your animal’s efficiency, and negatively impacting your operation’s bottom-line.

Quarterly Update: Mold and Mycotoxin Report

Quarterly Update: Mold and Mycotoxin Report

Mold and mycotoxin levels are greater than prior years – especially in corn from the Eastern Corn Belt. Learn what Kemin Customer Laboratory Services (CLS) discovered, while evaluating corn samples for the presence of mold and mycotoxins. See the report.

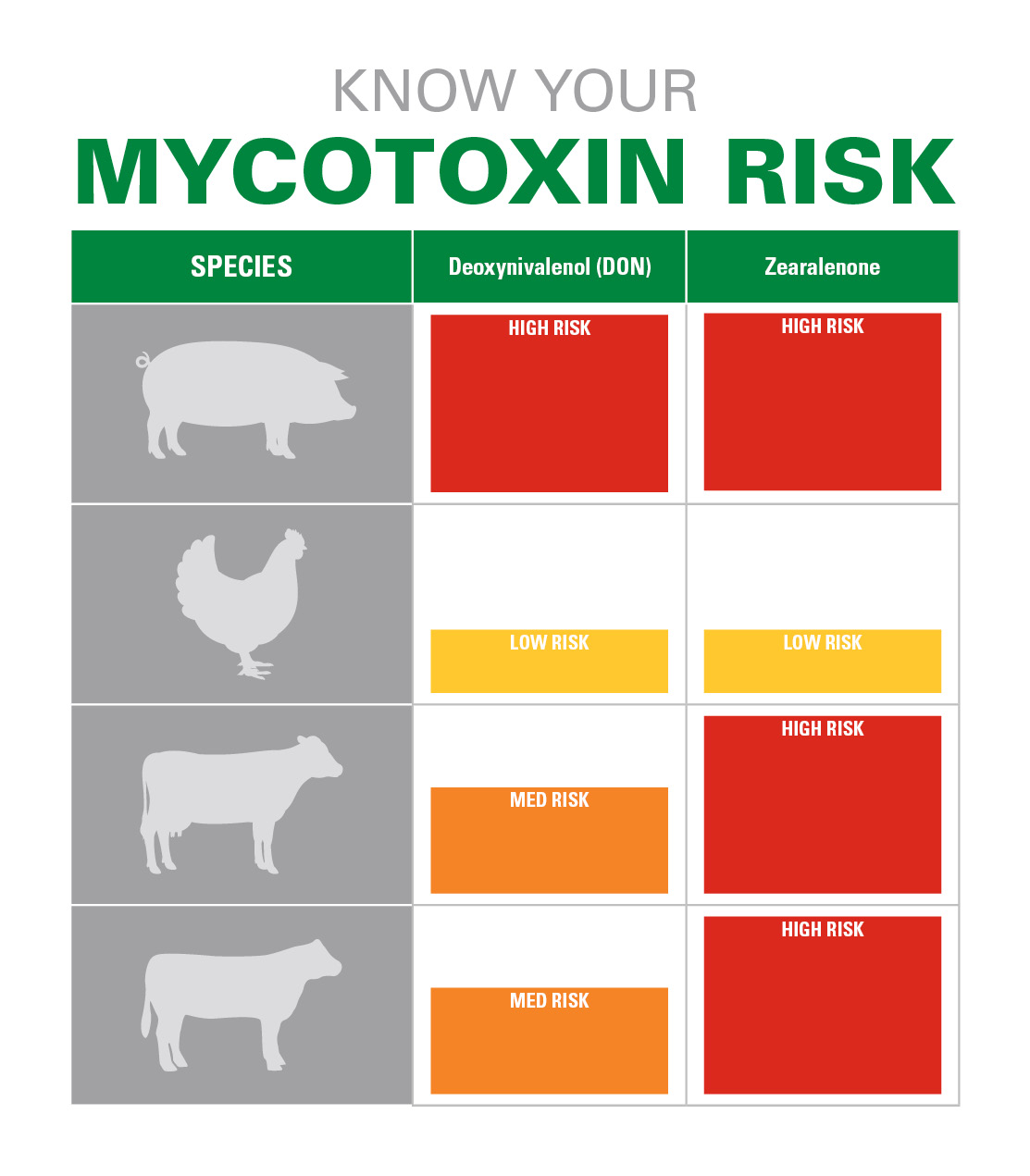

Are Oxidized Lipids Impacting Your Animal's Performance?

Are Oxidized Lipids Impacting Your Animal's Performance?

Fats and oils – or lipids – are an essential energy-source in nearly every animal’s diet. However, lipid sources used in feed formulations today – vegetable oils, rendered animal fats, recycled restaurant grease and more – are not all created equal. Inconsistency in the properties of lipids, their quality and nutritional value are common concerns for producers.

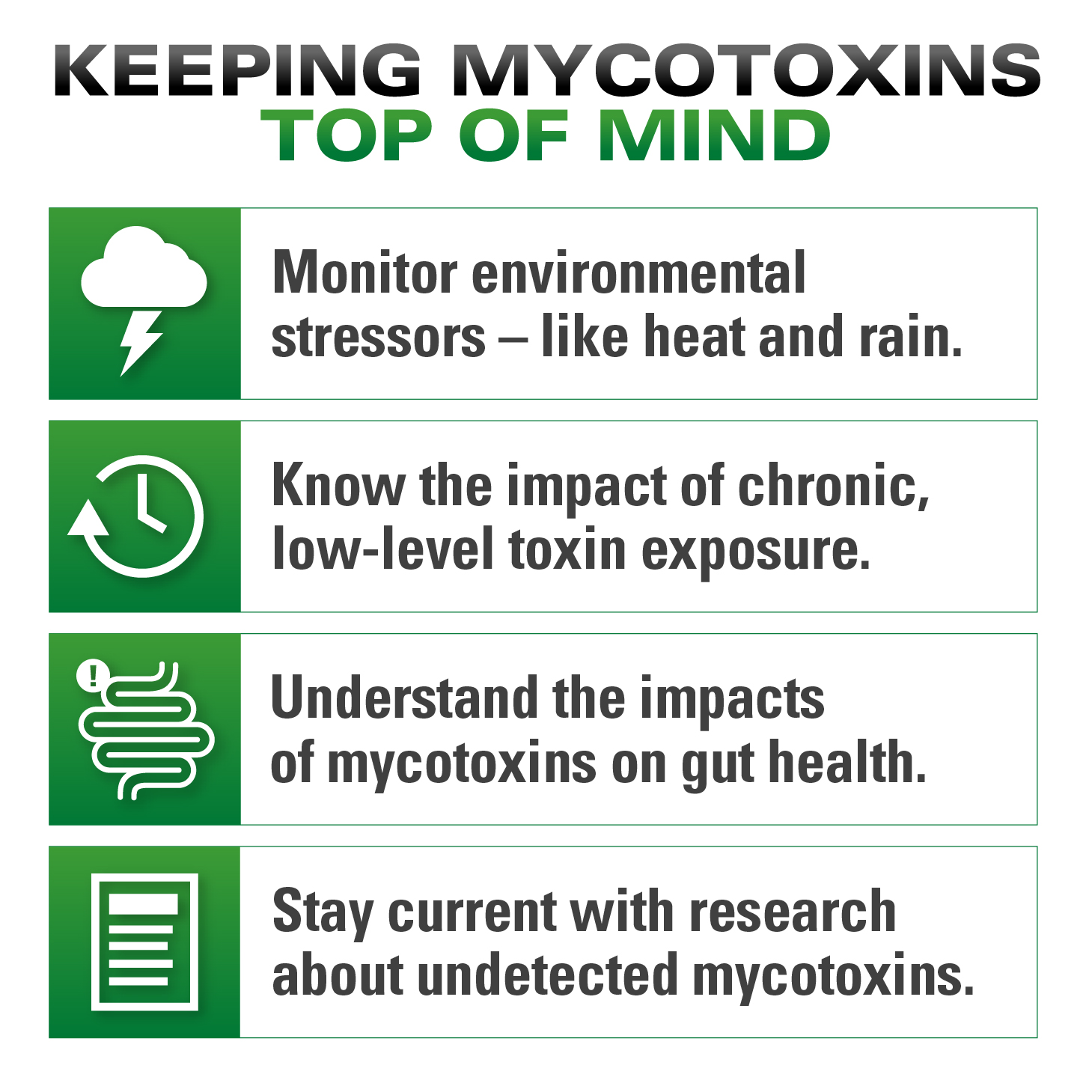

Four Reasons Mycotoxins Should be Top of Mind This Year

Four Reasons Mycotoxins Should be Top of Mind This Year

For producers to properly address the perennial mycotoxin challenge, understanding the risks mycotoxins pose to herd or flock health and performance is key. Furthermore, with many mills switching from old crop to new crop grains, it’s the perfect time to fine-tune mycotoxin strategies. Knowing what mycotoxins are in your grains is critical, but it’s also important to remember that not all mycotoxins – or their negative effects – are easily detected. So, what mycotoxin risks should be top of mind this year?

Quarterly Update: Mold and Mycotoxin Report

Quarterly Update: Mold and Mycotoxin Report

With the third largest corn crop in history, learn why corn prices are nearing $5.00 per bushel ($178/US ton), as well as what Kemin Customer Laboratory Services (CLS) discovered, while evaluating corn samples for the presence of mold and mycotoxins. See the report.

Emerging Mycotoxins: Undetected Risks in the Mycotoxin Minefield

Emerging Mycotoxins: Undetected Risks in the Mycotoxin Minefield

When producers think of mycotoxins, they often think of the big six: aflatoxin, deoxynivalenol (DON), T-2 toxin, fumonisin, ochratoxin and zearalenone. The primary effects of these toxins on performance and health of production animals are known, and regulatory guidance on threshold levels for these toxins in grains and feed exist. The problem is focusing in on these toxins alone equates to tunnel vision in the broader fight against the 300+ mycotoxins known to contaminate animal feed.

Preserve Lipid Quality During Extended Storage

Preserve Lipid Quality During Extended Storage

When it comes to preserving lipid quality, avoiding oxidation during storage is critical. Oxidized fats have reduced nutritional value and worse yet, contain harmful peroxides and free radicals, which can chip away at the health and performance of your herd. Heat, moisture and time conspire against fat and oil quality, increasing their susceptibility to oxidation. So, with many producers storing lipids longer — it's a good time to ask, "how is my fat looking?"

Preservation of Distiller Grains

Preservation of Distiller Grains

Corn-based ethanol production in the United States allows livestock and poultry producers the availability of dried distiller grains for use in rations. As with any by-product, the quality of these ingredients is highly variable. Because distiller grains are the by-product of ethanol fermentation, wet distiller grains (WDG) and distiller grains with solubles (DDGS) contain very low levels of mold and wild yeast, but quality can degrade rapidly if not stored correctly.

2020 Q3 Mold and Mycotoxin Report

2020 Q3 Mold and Mycotoxin Report

On July 10, 2020, the United States Department of Agriculture (USDA) released their World Agricultural Supply and Demand Estimates (WASDE). In this report, United States corn production was forecasted at 15.0 billion bushels. The national average corn yield is unchanged at 178.5 bushels per acre. Projected feed and residual use were 5.85 billion bushels and good, seed, and industrial was 6.625 billion bushels. Based off these, and other data, the USDA estimated the 2021 ending stocks will be 2.648 billion bushels, up 400 million bushels from 2.248 billion in 2020.

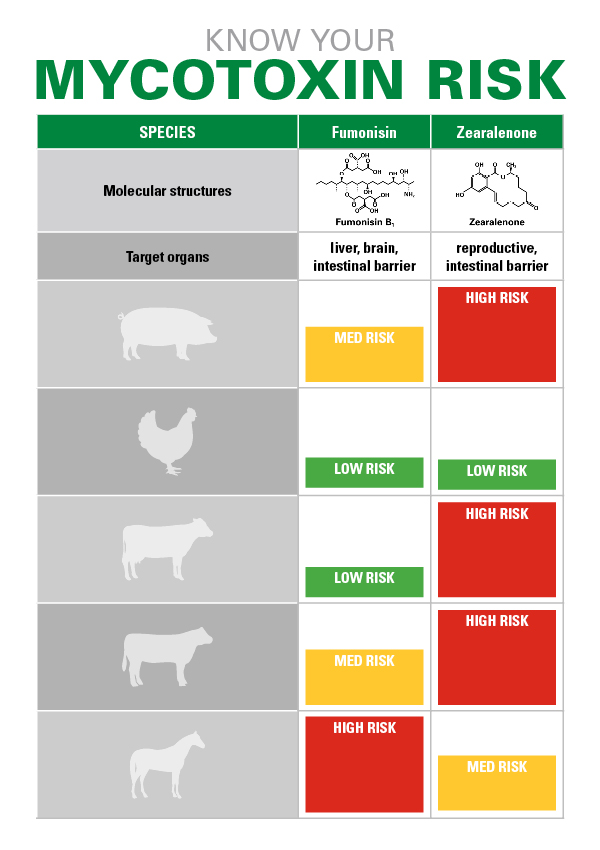

Mycotoxins are a costly, complicated problem for livestock and poultry producers. Not only are there hundreds of different mycotoxins, all produced by different fungi and environmental factors, but each category of toxins and each toxin within those categories can impact animals and birds differently. For producers, that means becoming aware of the major toxins and knowing the signs and symptoms of toxin exposure are critical to reduce the risk of mycotoxins eroding animal health and performance.

Changing Your Diets? Ingredient Quality Testing is a Must

Changing Your Diets? Ingredient Quality Testing is a Must

Managing feed costs has never been more critical to livestock and poultry producer profitability. But, as producers consider changing diet formulations to lower feed costs, it's critical to stress the importance of ingredient quality management. Understanding the risk factors associated with feed ingredients — new and old — is both practical and important.

>Dealing with Long-Term Storage of Bagged Feed

Millions of dollars in retail profit are lost each year due to returned feed. This is a shame because the two main issues related to bagged feed quality can be avoided with a good mold inhibitor and an effective antioxidant program. Mold and offensive odors are the first indication of poor feed quality. So, how do feed manufacturers ensure their retail partners do not face angry customers with feed quality issues?

Manage Vitamin Costs Through Preservation

Manage Vitamin Costs Through Preservation

Supplementing vitamins in the right amounts at the right time is critical for balanced animal nutrition. But balancing an animal’s nutritional needs and a diet’s formulation cost can become a nutritionist’s nightmare when vitamin availability is compromised, or prices are unusually high. Worse yet, reactive premix ingredients – choline chloride and inorganic trace minerals – can have an aggressive effect on vitamin destruction via oxidation. To manage vitamins costs, protecting vitamins from oxidation is key.

5 Tips to Prevent Vitamin Loss in Feed

5 Tips to Prevent Vitamin Loss in Feed

Not only are vitamins involved in over 30 metabolic reactions, but they also play key roles in managing internal cellular stress, immunological defense systems and the overall health of animals. So, although they make up less than 1 percent of the diet, vitamins are vital ingredients for optimal growth, health, reproduction and performance of livestock and poultry.

Know Your Mycotoxins and How to Knock them Down: Zearalenone and Fumonisin

Know Your Mycotoxins and How to Knock them Down: Zearalenone and Fumonisin

There’s bad news if you feed livestock: Nearly all of the world’s feed grain supply is contaminated with at least one mycotoxin. Almost 2/3 of corn harvested in 2018 that was tested by Kemin Customer Laboratory Services (CLS) was positive for mycotoxins. More importantly, however, nearly 50% of those samples contained multiple toxins.

Know Your Mycotoxins: T-2 and DON

Know Your Mycotoxins: T-2 and DON

Environmental stressors like extreme heat and management factors such as movement to new barns or housing units can cause a breakdown in an animal’s natural defenses. That’s when mycotoxins like trichothecenes (T-2 and deoxynivalenol (DON)) can infiltrate internal systems and cause sometimes severe — even fatal — damage when left unchecked.

Addressing Mycotoxins Helps Solve a Complex Problem

Addressing Mycotoxins Helps Solve a Complex Problem

Heat, energy, water and oxygen: they’re four essential elements critical to just about every form of life on the planet. Provided those things, even the most infinitesimally small organisms can flourish. In the case of mycotoxin-producing molds, that vigor can become costly for livestock producers. Mycotoxins are toxic secondary metabolites that are produced by mold in stored grain or growing plants. The production of mycotoxins is essentially a defensive response by the growing mold triggered by an environmental factor, like temperature, oxygen, pH or moisture.

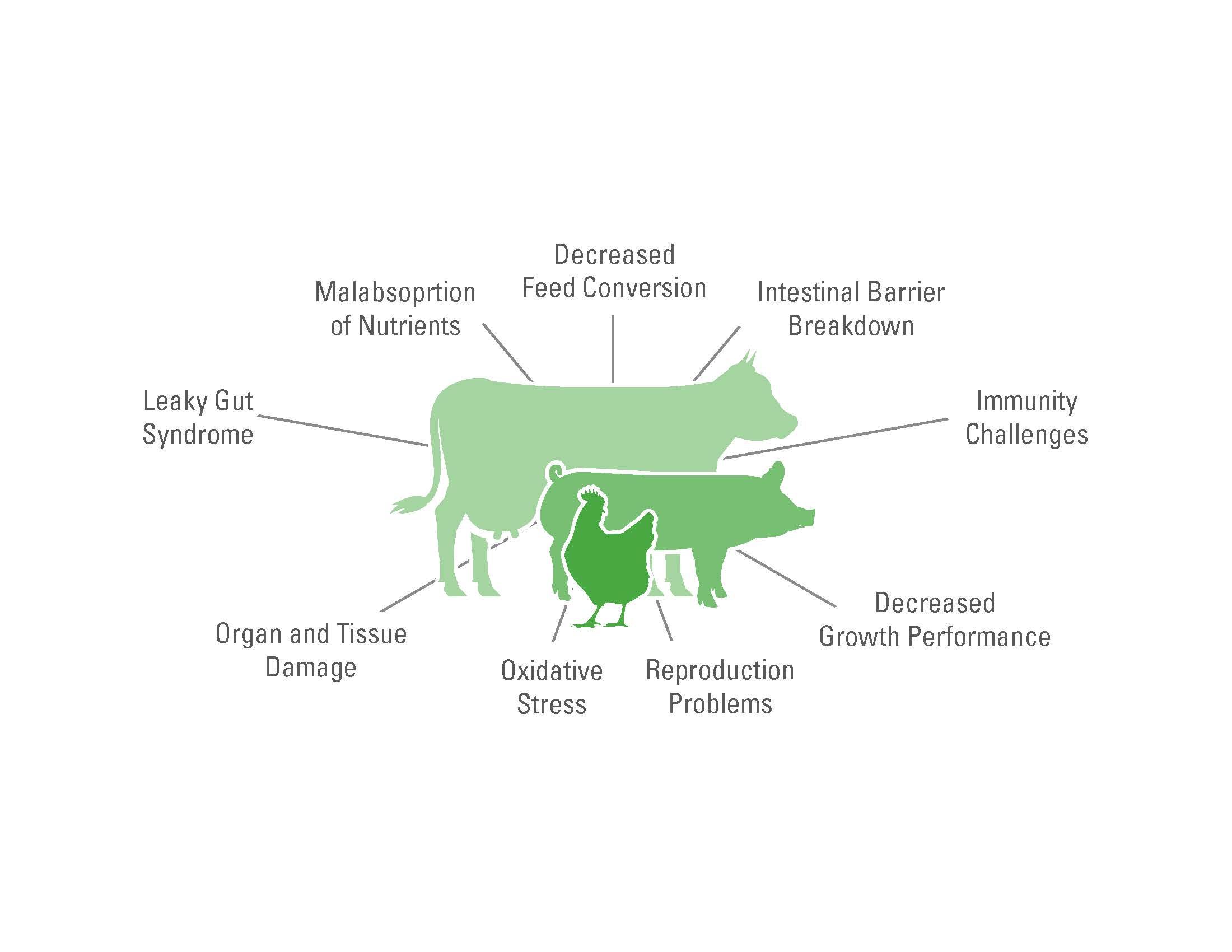

Using Aluminosilicate Anti-Caking Aids to Minimize the Impact of Mycotoxins on Performance

Managing mycotoxin contaminated feed ingredients is a constant challenge for animal producers. Mycotoxins are produced by both field and storage molds, and – even when fed at low levels – can have a detrimental impact on livestock and poultry performance. To make matters worse, grains are frequently contaminated with multiple mycotoxins, and research suggests toxic synergies may exist with certain mycotoxin combinations. Absorption of mycotoxins by the gastrointestinal (GI) tract may result in immunological dysfunction, malabsorption of nutrients and ultimately, losses in weight and performance.

Do You Know What's Happening in Your Fat Tank?

Do You Know What's Happening in Your Fat Tank?

What causes fats to oxidize? Time of storage, application of heat and the mixing of different lipid sources all have an impact on fat quality, and specifically on influencing oxidation. Oxidation is an irreversible, naturally-occurring process where fatty acids are attacked by free radicals resulting in production of harmful byproducts, including peroxides and aldehydes. This process reduces the energy value of the fat and can have deleterious effects on growth performance. Once oxidation starts, the damage cannot be undone, so preventing oxidation should be a top priority for producers.

Mycotoxin Management: What Can We Do Now?

Mycotoxin Management: What Can We Do Now?

Mycotoxins are toxic and/or carcinogenic molecules produced by growing fungi, specifically the various mold species which grow on plants. The toxigenic fungi involved in the human and animal food chains belong mainly to three genera: Aspergillus, Fusarium and Penicillium. Each of these molds can produce more than one toxin and some toxins are produced by more than one mold. Once we have mycotoxins in our crop, what options exist for livestock and poultry producers?

The hot summer weather is beginning to wind down now – but it’s always a good time to ask, “how is my fat looking?” Monitoring the quality of your incoming fat sources is the primary step in effective fat management. The impacts of oxidation are irreversible, so it is crucial to begin with high-quality fat and then maintain that quality. Oxidized fat that has been negatively impacted by heat, light and oxygen can have a damaging impact on your animals. This impact can be seen across performance, health and nutrition through decreased growth, immunity challenges, loss of energy content in the fat itself and an array of other issues.

Water. It is a major part of our everyday lives. It is one of the most essential components to our survival, and we take our access to a clean and safe water supply very seriously. The question is, do we put that same amount of emphasis on the quality of water we are providing to our livestock and poultry? Is the quality good enough to make you want to drink from your animals’ waterer?

Mycotoxins: Managing a Perennial Problem

Mycotoxins: Managing a Perennial Problem

Livestock and poultry producers are all aware of the presence of potentially-harmful mycotoxins in grain. It seems every day there is a new report declaring the newest hot spot for mycotoxin contamination. So, why does it suddenly feel like mycotoxins are found everywhere? A large reason for the increased focus on mycotoxin contamination is reporting. There is a growing database related to the detrimental impact that even low levels of mycotoxins can have on livestock production. With this increased awareness, the focus now shifts to signs and symptoms of mycotoxin contamination and what producers can do to mitigate their impact.

Don't Let it Go to Waste: 10 Tips for Long-Term Grain Storage

Don't Let it Go to Waste: 10 Tips for Long-Term Grain Storage

If you asked any farmer, they would agree that harvest is one of the best times of the year. Nothing brings that overwhelming feeling of satisfaction quite like watching the combine hopper fill with the fruits of their labor. During this time of "harvest celebration" it may be easy for one to think all the work is done. However, when it comes to maintaining the quality of grain after harvest, the work hasn't even started.

ENDOX®

KEM SAN®

MillSAVOR™

RENDOX®

Have a Question?

If you have a question about our products or services, or just want more information, fill out the form below and someone on our team will be in contact with you.

- California Residents

- California Supply Chain Act

- Canada Forced Labor and Child Labor Report

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies All rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.

Thank you for visiting Kemin.com.

Your questions and feedback are important to us. Let us know how we can help you learn more about Kemin, our products, our services or our website.

Interested in starting a career with Kemin?