You are viewing United States

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- Ultra CURB®

Ultra CURB®

Mold and Yeast Control for Animal Feed and Feed Ingredients

Ultra CURB® Liquid and Dry mold inhibitors are both highly concentrated blends of four powerful organic acids. The combination of acids is designed to target wild yeast growth, in addition to mold growth, to reduce total mixed ration (TMR) heating. Ultra CURB may be used on processed feed ingredients and all complete animal feeds.

The use of mold inhibitors in the livestock feed industry is a management tool used by producers to maintain feed quality. Hot, humid conditions promote wild yeast and mold growth in livestock feed. Kemin is recognized in the feed industry for pioneering the use of blended organic acids to control mold and wild yeast growth in feed.

Ultra CURB Liquid and Dry mold inhibitors are highly concentrated, synergistic blends of multiple organic acids designed to target wild yeast and mold growth to maintain TMR quality. Ultra CURB may be used on processed feed ingredients, complete animal feeds and added directly to the TMR.

Why is Mold and Wild Yeast Control Important?

Research has determined which organisms lead to TMR heating.1 Wild yeast species, such as Candida, Hansenula, Pichia, Issatchenkia and Saccharomyces, and mold species such as Aspergillus, Fusarium and Penicillium, all conspire to reduce forage quality and cause TMR heating.

Mold inhibitors are frequently used in the feed and livestock industry. Many producers use only one propionic acid with limited control against the key spoilage organisms. The combination of organic acids in Ultra CURB provide producers with control of most major spoilage organisms found in livestock feed.

How is Ultra CURB Different than Propionic Acid?

Ultra CURB is a highly concentrated blend of organic acids. Ultra CURB Liquid contains 82 percent total acid content and Ultra CURB Dry contains 42 percent propionic acid. Both feature a high inclusion level of propionic acid, as well as acetic, benzoic and sorbic acids. This combination of acids effectively targets wild yeast and mold growth in feed and feed forages to help stabilize TMR and reduce heating. This leads to a higher quality TMR.

What Trial Work Supports the Efficacy of Ultra CURB?

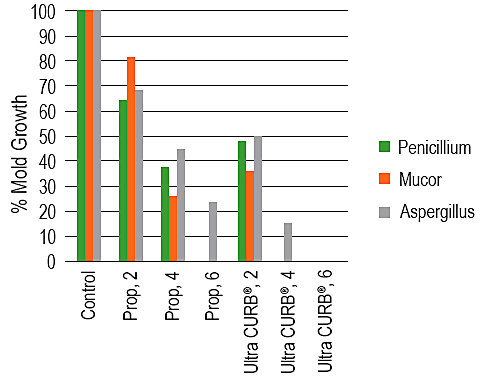

A study was conducted to help determine the efficacy of buffered propionic acid and a buffered, multiple organic acid mold inhibitor in controlling the growth of various mold species.2 This study compared a 75 percent buffered propionic acid to Ultra CURB Liquid, which is 82 percent total organic acids, for their abilities to control mold growth. In this study, strains of three common mold species were exposed to 2, 4 or 6 pounds per ton of each mold inhibitor. The results of this study (Figure 1) show that an application rate of 2 lbs/ton of propionic acid demonstrated the least amount of mold inhibition. Meanwhile, 2 lbs/ton of Ultra CURB resulted in similar levels of mold inhibition as 4 lbs/ton of propionic acid. When multiple organic acids are used in combination with each other, a greater degree of mold growth inhibition can be achieved.

Figure 1. Control of mold growth with various levels of propionic acid and Ultra CURB

Kemin has found the initial heating of livestock feeds is actually due to wild yeast.3 As wild yeast grows, moisture and heat are produced through cellular respiration. Because wild yeast consumes lactic acid as their energy source, this loss of acid generates a more optimal environment for mold growth.

Propionic acid is the most commonly used organic acid in mold inhibitors; however, acetic and sorbic acids, not propionic acid, are effective inhibitors of wild yeast growth.3,4

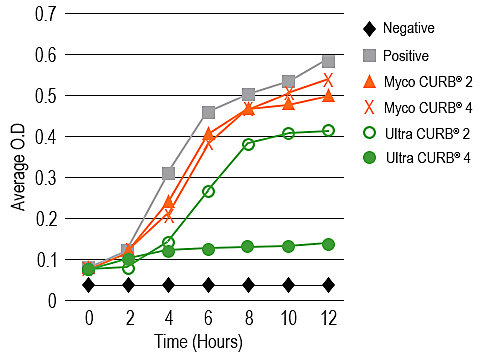

One study reviewed the efficacy of Myco CURB® mold inhibitor and Ultra CURB mold inhibitors in inhibiting wild yeast growth.4

Ultra CURB applied at 2 lbs/ton demonstrated rapid wild yeast growth for the first 8 hours, then little growth from 8-12 hours. When applied at 4 lbs/ton, no wild yeast growth was observed (Figure 2).

Figure 2. The impact of two mold inhibitors on Candida spp. yeast growth in the microtiter assay

Will These Concentrated Acids Harm Equipment?

These blends are buffered for improved equipment and employee safety. Ultra CURB extends shelf-life of complete feeds that contain a relatively high percentage of moisture. By preventing the proliferation of wild yeast growth, environmental conditions ideal for mold growth are delayed. Additionally, it delays the heating of TMR caused by wild yeast and mold growth.

Does Ultra CURB Come in a Dry Formulation?

In 2016, Kemin introduced Ultra CURB Dry. Feed manufacturers, dairy producers and beef operations have relied on Ultra CURB Liquid for many years—Ultra CURB Dry puts the power of a liquid into a convenient dry form.

The ingredients of Ultra CURB Dry have been carefully selected to provide broad spectrum control of the spoilage organisms most often found in TMR. TMR heating is caused by the growth of mold and wild yeast. The four-acid blend and scientifically-verified acid ratio found in Ultra CURB Dry means better control of TMR heating.

Product Specifications

References

1Limin Kung, Jr. Proceedings, 2010 California Alfalfa & Forage Symposium and Corn/Cereal Silage Conference. Visalia, CA. 1-2 December, 2010.

2Kemin Internal Document, 03-00810.

3Pelhate, J. 1973. Stabilisation de la mycoflore de maïs-grains humides ensiles. Ann. Tech. Agric. 22:647-661.

4Higgins, C., and F. Brinkhaus. 1999. Efficacy of several organic acids against molds. J. Appl. Poultry Res. 8:480-487.

Have a Question?

If you have a question about our products or services, or just want more information, fill out the form below and someone on our team will be in contact with you.

- California Residents

- California Supply Chain Act

- Canada Forced Labor and Child Labor Report

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies All rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.

%20-%20English_05.pdf/_jcr_content/renditions/cq5dam.thumbnail.319.319.png)

%20-%20English_02.pdf/_jcr_content/renditions/cq5dam.thumbnail.319.319.png)