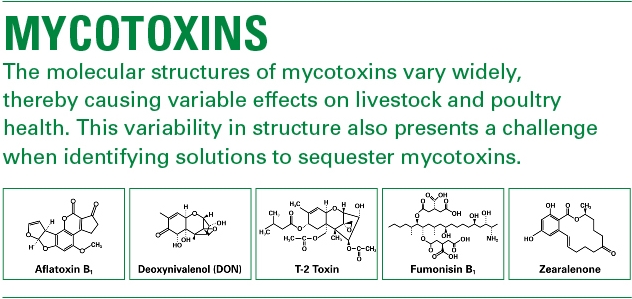

The act of binding with mycotoxin molecules — some of which are a mere five angstroms in length, a value equal to 0.1 nanometer (1 × 10-10 m) — most often takes place via molecular polarity. Binding molecules are typically around twice the size of the mycotoxins themselves, and essentially envelope the invading molecules, preventing them from attaching to gut tissues and developing larger infections. But binders must be made to tackle a specific toxin, thereby complicating the process of achieving total control.

“All mycotoxins are characterized by their shape and molecular structure. There’s a whole area of toxin-binder research to match up specific binders with the specific molecular structure of different mycotoxins,” Rodberg said. “Aflatoxin, for example, is relatively easy to bind because it’s structure features beta-carbonyl binding locations on either side of the molecule. For less polar toxins, currently there are enzymes being produced, and each one has to be made for a specific toxin. Getting rid of DON is different from getting rid of zearalenone. While polarity is the primary mode of action, we can’t bind with them all the same way, since some don’t have polar ends.”

Preventing Damage with KALLSIL™

Addressing mycotoxins depends on providing a supplement that has two key characteristics: first, the structural makeup that enables targeting of toxins, then the ability to effectively sequester and usher targeted toxins through the entire GI system to be excreted instead of allowed to bind with soft tissues in the gut lining.

This combination is readily available in KALLSIL, an enhanced zeolite mineral-based feed supplement that, among other benefits, helps reduce the effects of performance issues due to molds and mycotoxins taken in when an animal consumes contaminated feed. The inspiration behind using zeolite, a sodium calcium aluminosilicate mineral, comes straight from animal behavior observed for generations.

“We have strong supplier partnerships to provide zeolite with molecular openings the right size to make KALLSIL have a wide spectrum of efficacy,” Rodberg said. “With KALLSIL and what we’ve learned from a research standpoint, we’ve developed a product that has very strong capabilities to address feed quality problems.”

The specific molecular design of zeolite, the key ingredient in KALLSIL, helps the mineral capture more mycotoxin molecules, rendering them unable to cause inflammation that can lead to gut health issues and more systemic issues.

“We have a great zeolite mine we work with that can provide material with molecular openings the right size to make KALLSIL have a wide spectrum of control,” Rodberg said. “With KALLSIL and what we’ve learned from a research standpoint, we’ve developed a product that has very strong capabilities to address mycotoxins.”

The ROI of KALLSIL

Given the complexity of identifying mycotoxin damage, it can be difficult to define the return of supplementing KALLSIL to a beef, dairy, swine herd or poultry flock. But given the fact that there is such a high prevalence of mold and mycotoxin in feed grains around the world and the relatively low cost of adding KALLSIL to feed rations, Rodberg said there is virtually always payback.

“In our research over the years with performance drag and low-level mycotoxin infections, we found that when administering two pounds of an enhanced zeolite per ton of feed, one egg producer ended up with two more eggs laid per hen. That was a huge win for him,” he said. “Another producer was feeding his beef herd a ration with distiller’s grains and high-moisture ingredients and had an increased percentage of abortions in his heifers. The abortion rate returned to normal when the producer started giving them around 3-4 lbs./ton of an enhanced zeolite.”

The bottom line is there is a return with KALLSIL. Whether it is 5-1 or 10-1 depends on the feed quality problems the producer’s facing and how well he or she knows how the animals are performing.”

References

1Feng, G. H., and T. J. Leonard. 1998. Culture conditions control expression of the genes for aflatoxin and sterigmatocystin biosynthesis in Aspergillus parasiticus and A. nidulans. Appl. Environ. Microbiol. 64:2275-2277.

2Guzman-de-Peña, D., and J. Ruiz-Herrera. 1997. Relationship between aflatoxin biosynthesis and sporulation in Aspergillus parasiticus. Fungal Genet. Biol. 21:198-205.

3Buchanan, R. L., Jr., and J. C. Ayres. 1975. Effects of initial pH on aflatoxin production. Appl. Microbiol. 30:1050-1051.