You are viewing Asia Pacific

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- millSMART™

- millSMART™ Surfactant Technology

millSMART™ Surfactant Technology

Kemin Surfactant Technology – Improving Moisture Absorption and Retention in Feed

millSMART™ milling aids are formulated with Kemin Surfactant Technology to maximize absorption and retention of added moisture in all types of animal feeds.

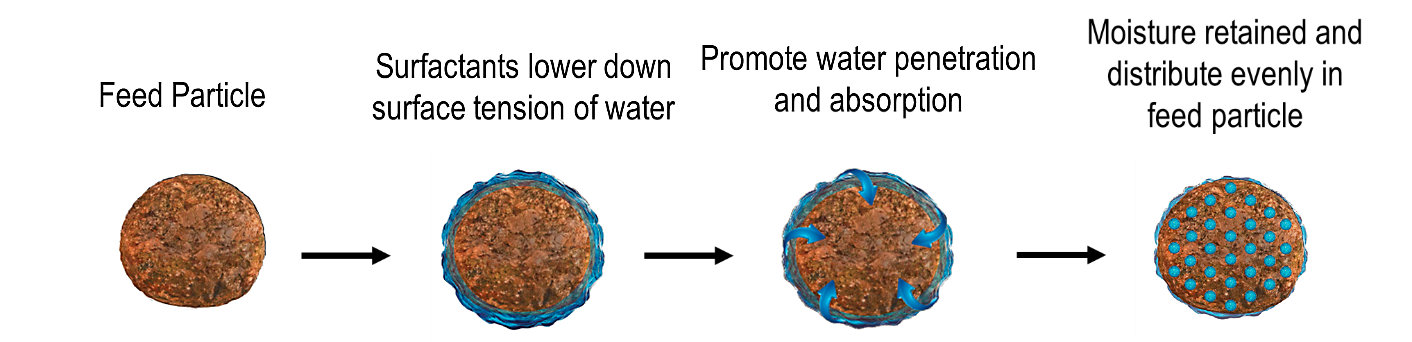

The synergistic blend of surface-active agents in the millSMART™ milling aids instantly reduces the water surface tension. Upon contact with the feed particles, water with reduced surface tension can be more effectively absorbed and retained evenly in the feed particles (Figure 1).

Figure 1. A cross-sectional schematic diagram to show how millSMART™ milling aids improve moisture absorption and retention in the feed.

Preconditioning Feed with millSMART™ Milling Aids

By preconditioning the feed with water mixed with millSMART™ milling aids more moisture can be retained and distributed evenly within the feed particles, improving starch gelatinization during conditioning. This improves feed digestibility and pellet durability, resulting in fewer fines and wastage.

As moisture is better and more evenly retained in the feed particles preconditioned with millSMART™ milling aids, moisture loss is minimized during the cooling phase of the pelleting process.

Preconditioning Feed with Water Alone

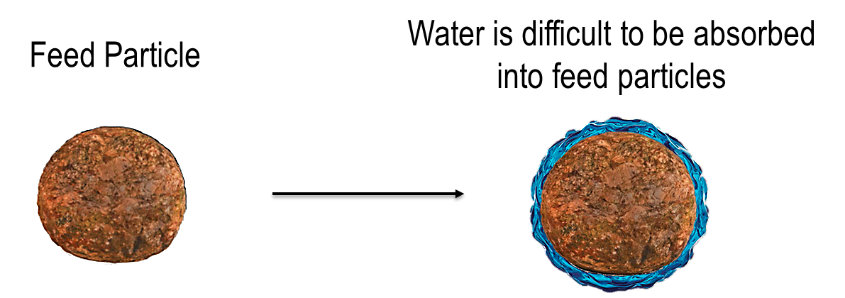

Preconditioning feed by adding water alone into the feed mixer is not effective. Water has a strong surface tension (~72 mN/m at room temperature), preventing it from effectively penetrating through the feed particles (Figure 2).

Figure 2. A cross-sectional schematic diagram to show the strong surface tension of water prevents it from being effectively absorbed into feed particles.

By preconditioning the feed with just water, moisture cannot effectively penetrate through the feed particles. This limits the moisture absorption and retention within the feed particles. Starch gelatinization is not optimal, resulting in lower feed digestibility and pellet durability.

With poor moisture retention in the feed particles, the feed is also more susceptible to losing moisture during the cooling process.

Have a Question About millSMART™?

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies All rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.