You are viewing South Asia

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- RENDOX®

RENDOX® Liquid

RENDOX® - Preserving Fat Quality

Oxidation effects on fat quality can be a major factor in the reduction of livestock and poultry feed quality. The oxidation effects on fat quality is an irreversible, naturally occurring process where fatty acids are attacked by free radicals and oxygen is absorbed. Initiated when fat is exposed to oxygen, metal ions, heat, enzymes and light, this process results in a conversion of fatty acids into harmful byproducts including peroxides and aldehydes. Oxidation dramatically affects the quality of fats and oils, which has been shown to have direct impact on animal health and performance, ultimately negatively affecting your business' financial bottom line.

To protect your fat from negative oxidation effects on fat quality, an antioxidant system should be used. The benefits of antioxidants on fat quality include longer shelf-life and stability of the lipid source and protection agains the development of toxic compounds including peroxides and aldehydes.

An antioxidant system should contain a combination of the following:

- Synergistic blend of antioxidants to absorb free radicals before they destroy fatty acids

- Metal chelators to bind metal ions, which may promote free radical oxidation

- Oil-based carriers to better mix with fat molecules

Not all fat is the same. Due to this fact, all lipid sources should not be treated with the same antioxidant. Kemin has conducted years of research to develop specific blends of antioxidants for animal fats including Choice White Grease, Poultry Fat and Tallow. When considering antioxidants for vegetable fat, RENDOX® CQ was developed precisely to address the distinct fatty acid profiles of vegetable fats including corn and soybean oils. Finally, when purchasing fat sources which are a blend of vegetable oil and animal fats, Kemin created antioxidant for fat blends as well. You can be assured that Kemin has your antioxidant needs covered, regardless of your lipid source.

Kemin Antioxidant Systems

| Ethoxyquin (EQ) Inclusion |

|||||

| Product | Animal Fats | Vegetable Oils | Blends | Low EQ | No EQ |

| Liquid Products | |||||

| RENDOX® AET | X | X | |||

| RENDOX® AT 20 | X | X | |||

| RENDOX® CQ | X | X | |||

| RENDOX® RG | X | X | |||

| RENDOX® AC | X | ||||

| RENDOX® EQ | X | ||||

What's Happening in Your Fat Tank? Benefits of Antioxidants on Fat Quality

Fat quality solutions start with the purchasing of quality fat. However, high quality fat can easily be negatively impacted due to handling and storage conditions. Time of storage, application of heat and the mixing of different lipid sources all have direct implications on the production of peroxidation compounds.

Management practices implemented often focus on the amount of time fat is exposed and susceptible to oxidation. Unfortunately, this practice does not consider the layer of fat residue, which coats the inside of the tank, or the sludge buildup at the bottom of the tank. These residues contain high amounts of free radicals, which, once mixed with new fat, disperse and immediately promote oxidation of the new fat.

Treating fat with a Kemin antioxidant system will prolong the fat quality, ensuring you receive the maximum value from your fat.

Case Study: Stabilizing Fat Tank Quality

Background

Previous fat quality testing indicated the customer feed mill in this study was receiving high quality, non-antioxidant treated poultry fat. The customer's fat tank was not being cleaned, causing concern that the quality of the fat leaving the tank was not the same as the quality of the incoming fat.1 The customer wanted to know, was an antioxidant for the animal fat needed?

Kemin Customer Laboratory Services (CLS) field study was conducted to determine:

- Quality of fat coming out of the tank

- Correct antioxidant system treatment level, if needed

Project Scope

The fat tank at the customer site was sampled three times per week (Monday, Wednesday and Friday) for three sampling periods.

- Sample Period 1: Prior to implementation of the antioxidant treatment

- Sample Period 2: 2 weeks post implementation

- Sample Period 3: 4 weeks post implementation

Analysis Tests Conducted

| Oxidative Stability Index (OSI) |

A test illustrating the potential for oxidation in a liquid fat. Results are reported in hours to induction (onset of oxidation), a higher value is more desirable. |

| Peroxide Values (PV) |

Peroxides are the initial compounds produced by oxidation and are early indicators of active oxidation. |

| Secondary Oxidatives |

Testing for aldehydes, such as hexanal and 2,4-decadienal. These compounds are produced later in the oxidative process, following peroxides. |

Oxidation Analytical Testing Results

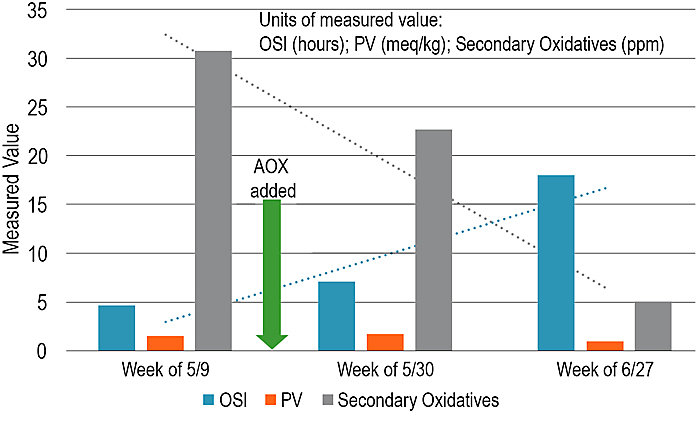

Figure 1. Change in oxidative status of poultry fat before/after implementation of an antioxidant system (n = 3 for each designated time period)2

As the results of the field demonstration indicate, once high quality poultry fat was added to the untreated fat tank, blending of the fats allowed for the poor quality, free radical-loaded fat to immediately impact oxidation. The first series of samples confirm low OSI times and high levels of secondary oxidatives. After implementation of the antioxidant treatment system, the benefits of antioxidants on fat quality were seen right away. OSI begins to increase, indicating improved stabilization of the fat. In addition, secondary oxidative levels begin to decrease, signifying interruption of the oxidative process.

Stabilizing the quality of the previously untreated fat tank takes time. Even as new fat is added, OSI times and secondary oxidative levels continue to improve.

References

1Kemin Internal Documents, 16-00129, 17-00011.

2Kemin Internal Document, 16-00090.

Contact Kemin Animal Nutrition & Health - India

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements