Service to Customers: Partnership Beyond Ingredients

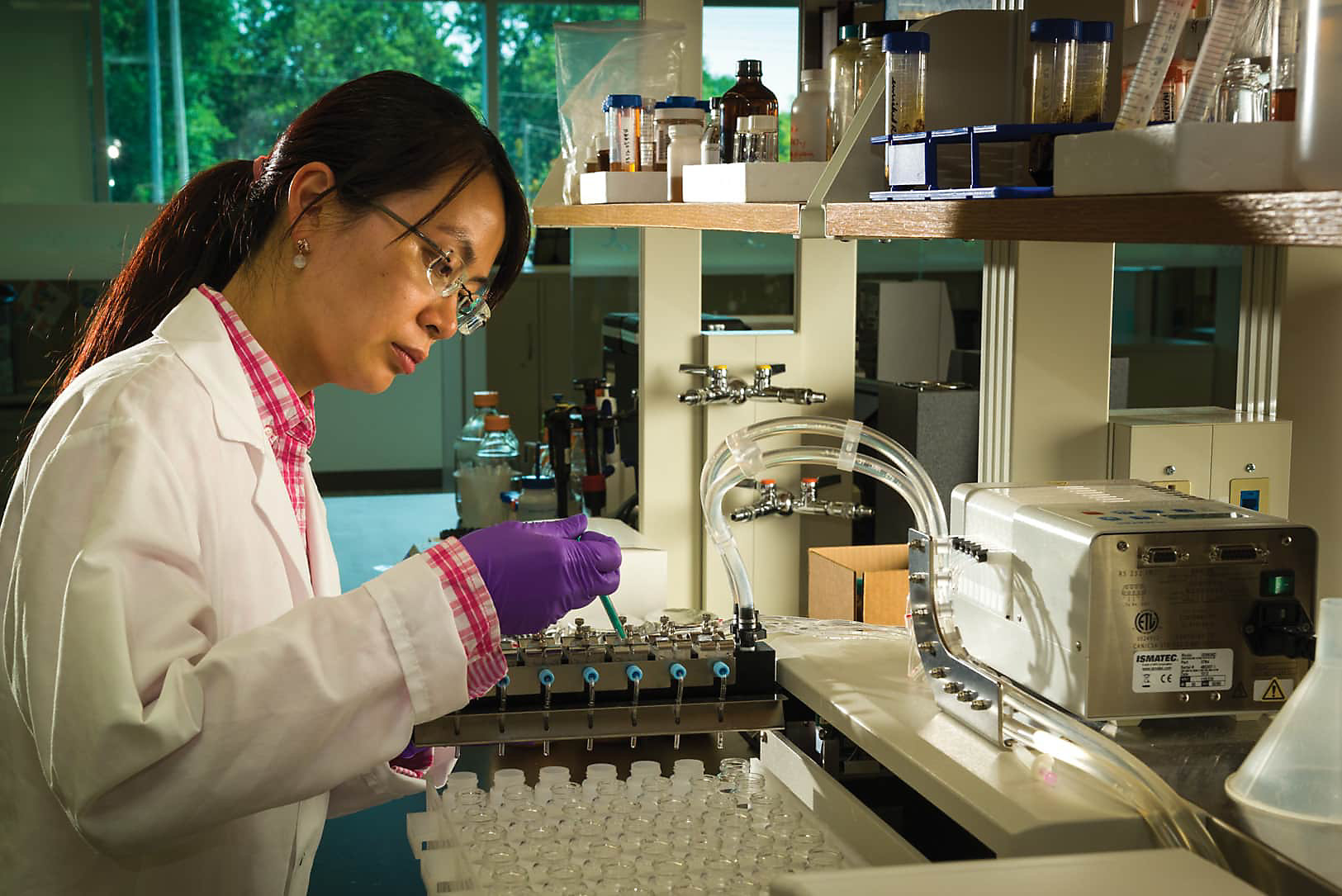

At Kemin, we view our customers as partners. Their success drives our innovation, and it’s why we go beyond simply supplying ingredients. Through tailored services, technical expertise, and a commitment to quality, we help customers maximize the value of every Kemin product.