Frying food has been a popular way of cooking around the world for ages. The oil for deep frying causes a pleasant change of flavor, texture and colour, and it’s a speedy cooking method. Moreover, there is a trend towards healthier vegetables oils, which have a shorter frying life. However, frying is a complicated, multi-factor process where the frying oil undergoes a complex series of oxidation reactions.

You are viewing EMENA

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Food Technologies

- FORTI-FRY™

FORTI-FRY™

This affects both the quality of fried food and the deep-frying medium. Frying oil oxidation results in an increased foaming.

This product is also suitable for plant-based solutions.

Prevent oxidation when frying with FORTI-FRY

FORTI-FRY is a natural antioxidant consisting of tocopherol rich extract and specialty oils that significantly extends the life of frying oil. It prevents the formation of undesirable compounds and off-flavours. Furthermore, FORTI-FRY ensures foaming reduction and provides an optimal heat transfer which results in even browning of the food from the first batch onward.

FORTI-FRY extend your oil frying life naturally

FORTI-FRY provides the frying industry with a proprietary, heat stable solution that withstands high-temperature processing. The natural antioxidant ensures that the quality and nutritional value of the frying oil and the fried products is maintained, as expected by the consumer. How can I review the quality of my frying oil? There is no direct correlation with the colour change and the deterioration of fat. Oil can turn dark quickly, while still having a good oxidative status.

FORTI-FRY natural antioxidant well received at Food Ingredients Europe

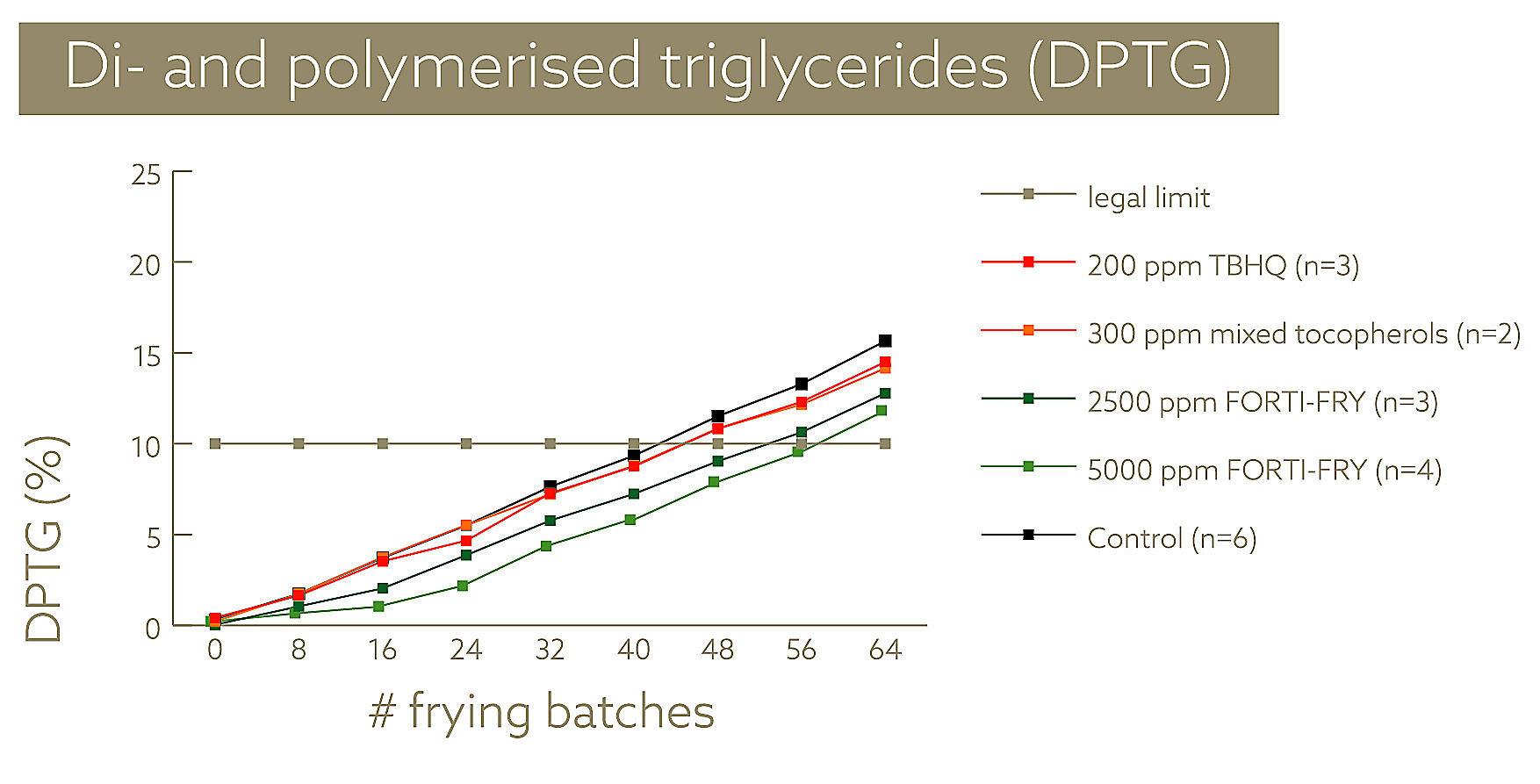

On the other hand, chemical parameters such as the concentration of total polar compounds (TPC) and dimerised and polymerised triglycerides (DPTG) are widely accepted parameters to decide whether the used oil should be replaced. So it’s not just about the colour degradation of the oil.

Go further and discover our FrySMART™ program

Kemin answers your burning questions!

Disclaimer: Product allowance and labelling may differ based upon government requirements. Certain statements may not be applicable in all geographical regions.

Products

Careers

Careers

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.