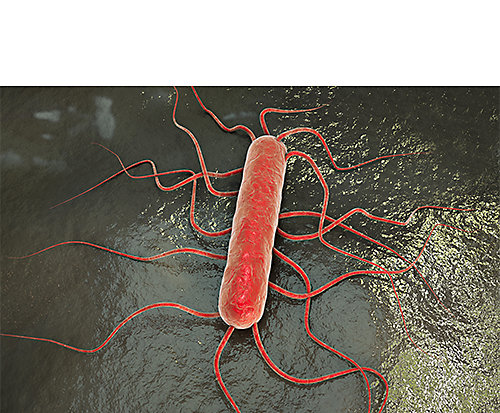

Bacteria

You are viewing EMENA

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Food Technologies

- Ensuring Food Safety

Ensuring Food Safety

Consumers Expect their Food to be Safe

When consumers purchase food, not only do they expect it to taste good, but they also expect that the product is safe for them to eat.

The Risk of Recall

When a food product has been identified as contaminated, a recall occurs. Not only does a recall have direct costs for your company, but it has many indirect costs as well.

A study done by the Food Marketing Institute and the Grocery Manufacturer’s Association found that the average cost of a recall for a food company is $10M in direct costs. However, these are not the only costs food manufacturers incur during a recall. Loss of sales and litigation fees are just some of the initial damages. One of the most significant losses during a recall is your brand reputation with your consumer. Consumers expect safe and flavourful food. When your brand fails to deliver safe food, consumers may choose to stop purchasing not only the recalled product, but everything falling under that brand due to safety concerns.

What Causes Food Recalls?

There are three common types of food recalls:

• Undeclared Allergens

• Foreign Materials

• Microbial contamination

While all three are significant, microbial contamination is the one that has significant impact due to its severity and number of illnesses they cause.

Microbial Spoilage

There are three types of microbial spoilage that concern food manufacturers:

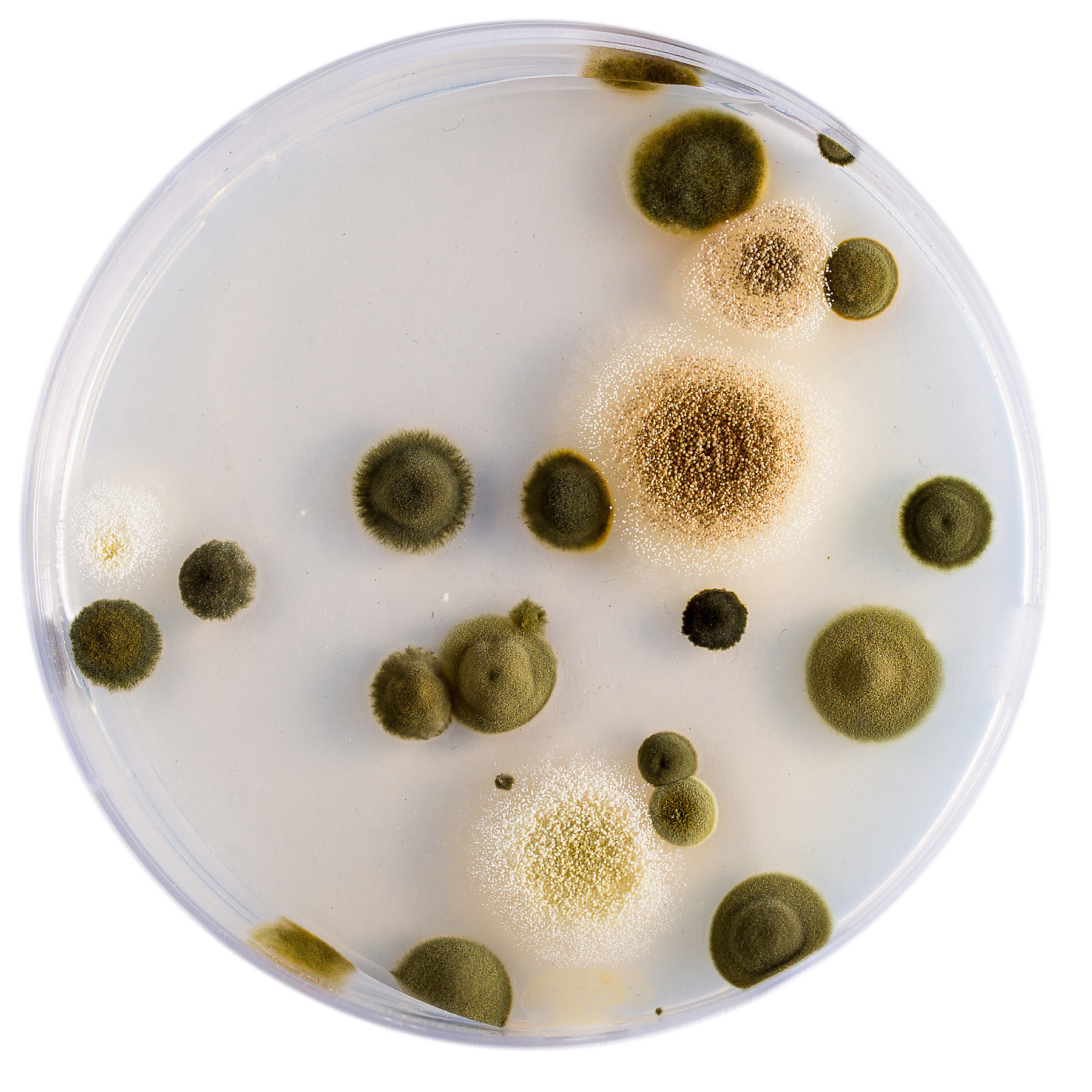

Mould

Yeast

These three types of spoilage can be introduced into a food system in a variety of ways. Common sources of microbial contamination include: equipment, air, water, sanitation practices, people, packaging, food build-up and ingredients.

How does microbial spoilage affect my food?

Microbial spoilage is often a major factor affecting the shelf life of food. Baked goods, specifically those with a higher water activity, are especially susceptible to mould. The water activity of meat and poultry products also makes them highly susceptible to microbial spoilage and food-borne pathogens.

Food Safety Experts

At Kemin, our experienced technical team uses their extensive know-how to develop solutions that positively affect food safety. We offer food safety solutions as well as mould inhibitors to help control microbes and prevent spoilage and mould growth for a variety of matrices, helping you solve your food safety challenges.

Food Safety Control Solutions

Mould inhibitor for Bakery products and Snack Applications

• Liquid mould inhibitor to control microbes, prevent spoilage and mould growth

• Economical cost-in-use

• Better dispersion over dry ingredients

Food safety ingredient for meat and poultry products

• Buffered vinegar food safety solution for protection against spoilage bacteria in meat and poultry products

• No negative effect on meat quality, colour or flavour

• Dry, liquid and certified organic varieties available

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.