Maintaining visual appeal and flavour quality remains a challenge for meat manufacturers due to oxidative rancidity and microbial spoilage. Colour is the main aspect that defines the quality of fresh meat products and it is the most important criterion consumers use in selecting fresh meat.

Equally important to red colour in fresh meat is brown or grey colour in cooked meat and pink colour in cured meat. It is estimated that nearly 15% of retail beef is discounted in price because of surface discolouration, which is equivalent to annual revenue losses of one billion1.

A survey conducted by Carr and Miller in multiple retail stores revealed that poor colour was both the most common reason pork packages were deemed unacceptable (63.3% of responses) and the most common reason pork products were removed from display (43.3% of responses). They described poor colour as grey (50%), greyish green (36.7%), light green to brown (10%) or too dark (3.3%)2.

Whereas colour is a crucial factor for a first purchase, a fresh and consistent flavour will convince the customer to buy the same meat product again.

Myoglobin Chemistry and Colour

Myoglobin is the heme protein primarily responsible for meat colour. Myoglobin concentration varies between and within animal species and is affected by factors such as age, sex, diet, genetics and environmental factors. The concentration of myoglobin per kilogram of lean meat is the highest in beef, followed by lamb, pork and poultry3.

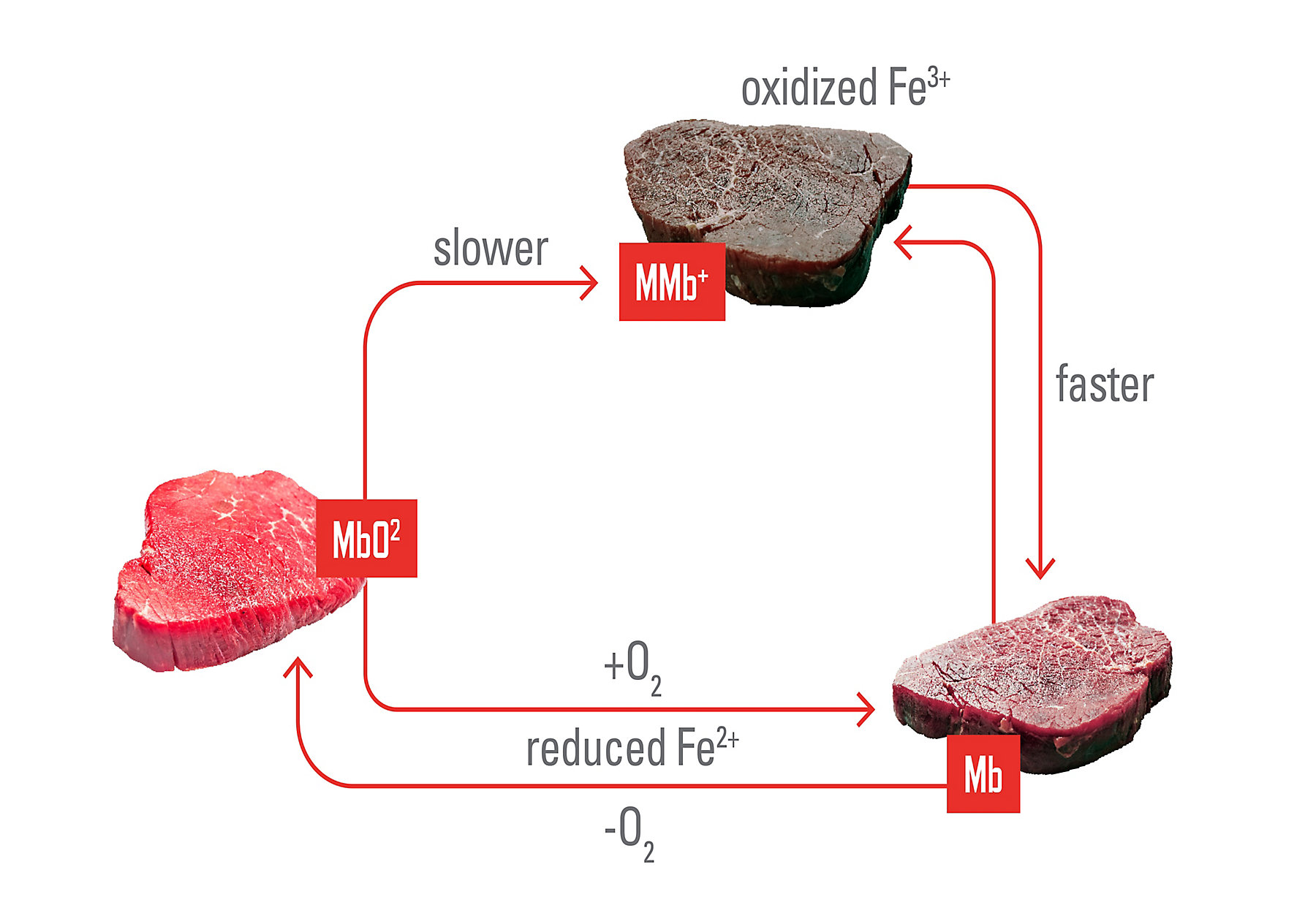

Myoglobin is present in three different forms, which are in equilibrium with each other (Fig.1). Stable oxymyoglobin (MbO2) is formed in an oxygen rich environment and has a bright red colour which is considered a mark of quality. Fresh cuts of meat consequently are red on the outside (up to a depth of about 1 cm). Inside the thicker pieces, oxygen cannot penetrate well and a higher presence of myoglobin (Mb) brings about a more purple colour. Over time a continuous oxidation will transform Mb into metmyoglobin (MMb+) which has a brown colour due to the oxidation of the heme iron from Fe2+ to Fe3+. Consumers perceive this colour change to brown as a cue that the meat is no longer fresh.