It is often said that breakfast is the most important meal of the day. And what we eat is defined by our culture and therefore breakfast trends widely differ throughout the world. With influencers online pushing in new trends, we also see a shift towards more healthy food choices, and today, you can find international cuisine in a local supermarket. We at Kemin Food Technologies have developed label-friendly food safety and shelf life solutions to address most, if not all, of those trends.

CEREALS

Granola, oats, nuts, seeds, … From very healthy to sugar infused sweets, cereal-based breakfasts are perhaps the most widespread throughout the world. While nuts and cereals are dry foods with a good shelf life, the time that they keep their best quality is limited. But the microbiology and safety of cereal grains and cereal products is a very important area, while also maintaining their sensory appeal to the highest possible levels. And we’ve noticed that the oils inside untreated cereals and nuts, turned rancid relatively fast, resulting in significant flavour loss.

With FORTIUM® R, muesli and other breakfast cereals and oats showed a flavour improvement and a very high oxidative stability. Therefore, we can store cereal-based products at ambient temperatures and in warmer conditions, while preserving their flavour profile. In our studies products treated with FORTIUM R were unanimously preferred over untreated cereals.

BREAD

However far we travel, bread is a food product literally every culture has in some form. But because of its limited shelf life and relatively fast deterioration process, losing its sensory appeal, especially in the Western world, a lot of bread is tossed away in the trash. We determine physical changes, chemical changes, and microbial growth, when talking about spoilage of baked goods. That’s where we come in, looking for antimicrobials, mould inhibitors and shelf life solutions in the fascinating world of natural plant extracts and natural antioxidants.

At Kemin, we understand how different factors—such as mixing procedures, baking and storage temperatures, water activity, and pH—affect the shelf life and sensory appeal of bakery and confectionery products. Our solutions address the needs of modern-day consumers who want their products fresh and delicious for a longer period. From simple solutions to complex blends, we help our clients solve their profit margin challenges.

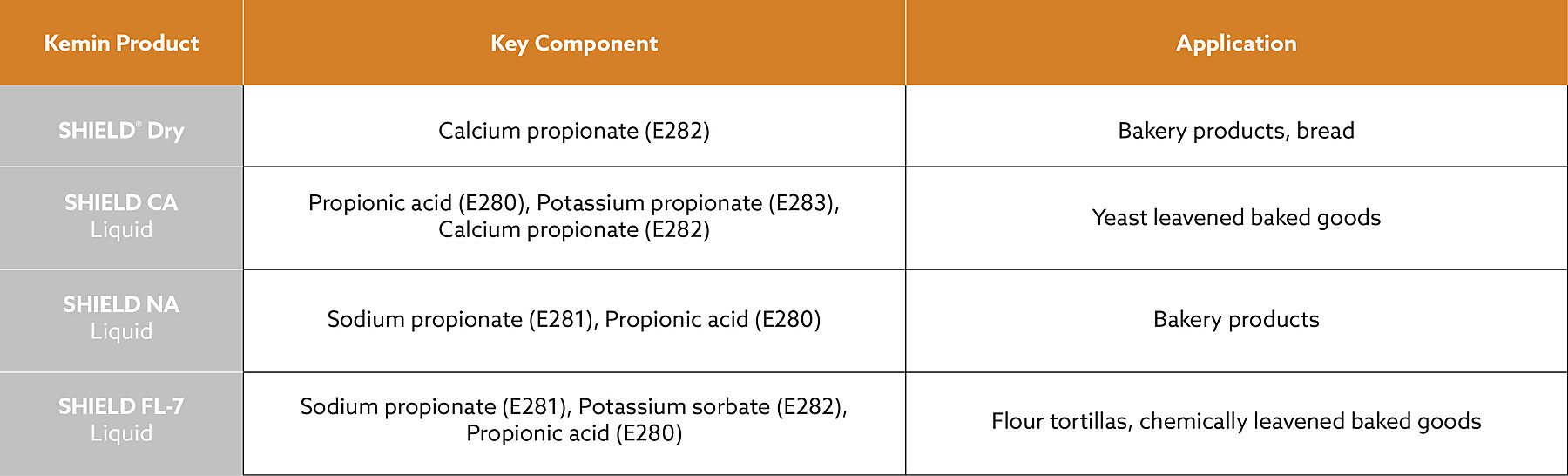

We are proud to say that Kemin is the global leader in liquid technology for antimicrobial food protection. For tortilla products, we offer SHIELD® Liquid. This food preservative will delay microbial spoilage because our formula affects all the base ingredients of the finished bakery product. SHIELD Liquid provides homogenous, even dispersion throughout the dough. Furthermore, the product eliminates irritating dust that is common with dry preservatives. As a result, SHIELD Liquid improves handling without affecting taste.

For bread products, bakers prefer dry Ingredients because of convenience and user-friendliness of adding those to other dry pre-mixes and ingredients. Kemin offers SHIELD Dry calcium propionate to help them keep their bread products free from moulds.

DELI MEATS

In many cultures bread is accompanied with deli meats such as ham and salami. These processed meats have a longer shelf life than fresh meat products, yet their sensory appeal remains limited. Maintaining visual appeal, flavour quality as well as meat safety remains a challenge for manufacturers due to oxidative rancidity and microbial spoilage. Colour is the main aspect that defines the quality of cooked ham and the most important criterion consumers look for when selecting deli meat.

Studies have shown that meat quality covers inherent properties decisive for the suitability of the meat for further processing and storage including retail display. When cooked ham is exposed to retail light, the pink colour fades rapidly. In our study, ham that was exposed to light lost colour and a yellowish greyish discolouration was observed even though ascorbates, citrates and nitrite were already added.

Microbial spoilage is a key factor in the shelf life of a variety of protein rich food products. Testing has shown that vinegar-based ingredients protect Ready-to-Eat (RTE) breakfast products like smoked salmon, deli-meats and deli-salads from spoilage bacteria. BactoCEASE® NV is a buffered vinegar-based solution and an alternative for synthetic ingredients. It has a balanced flavour profile and can prolong shelf life of ham with 21 days.

HAZELNUT SPREAD

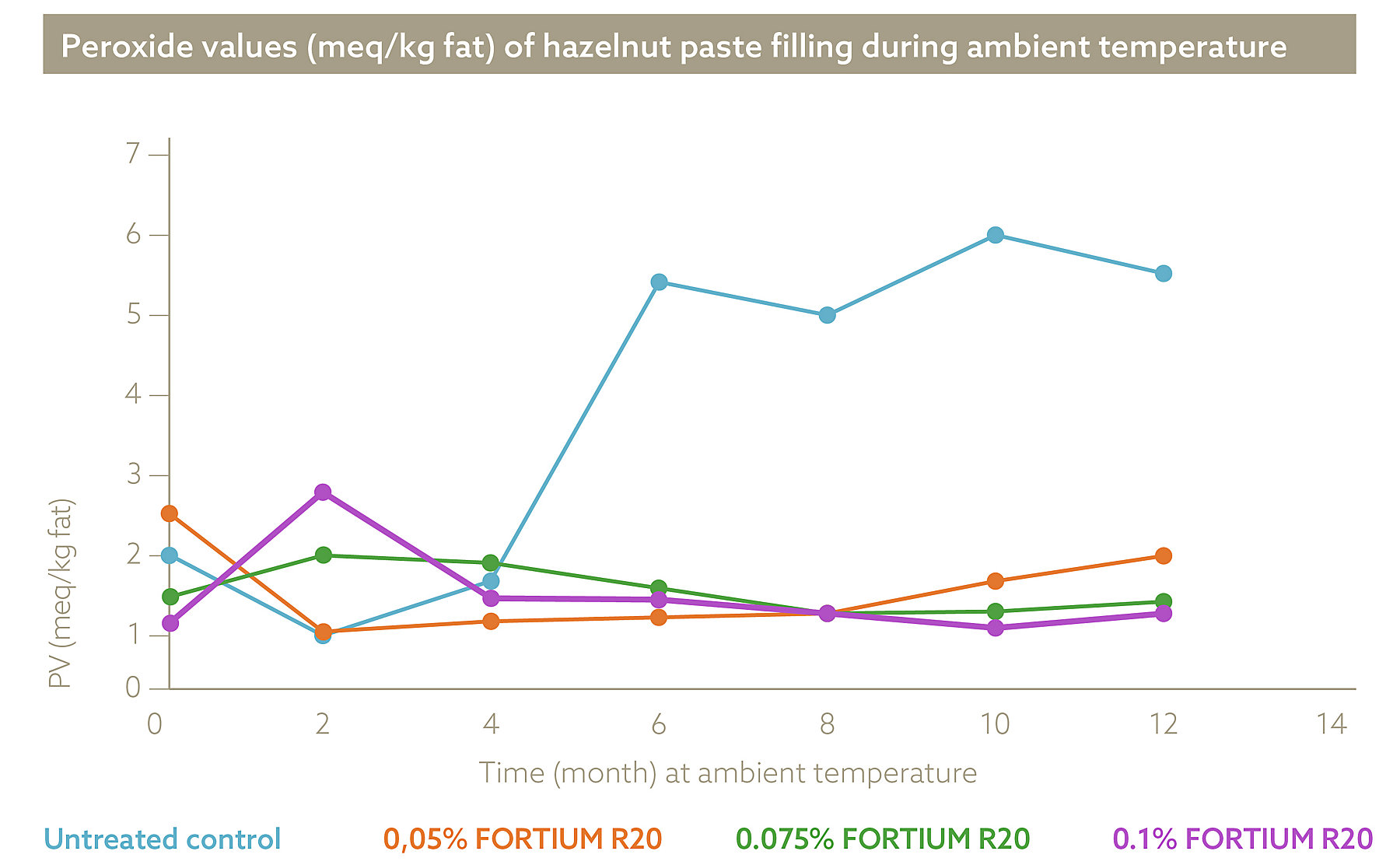

Whether spread on toast or dolloped on pancakes, the world, and Europe in particular, loves a nutty, chocolate topping for breakfast, or any given moment of the day. But also bite-size products with chocolate-hazelnut fillings are widely popular. Regularly such products have a shelf life of 12 months. But during this time, peroxide and p-anisidine values increase rapidly. At the same time, we’ve tested samples where our product FORTIUM R was added.

FORTIUM R improves the flavour profile and extends the shelf life of a hazelnut paste filling or spread by increasing its oxidative stability. The applied dosages also protect the overall quality when stored at ambient temperature. Furthermore, our studies demonstrate the required shelf life of 12 months could be ensured and exceeded using our label friendlyrosemary extract.

HOUMOUS

Increasing in popularity over the world, houmous often comes in the form of a dip or spread. Houmous is made from cooked, mashed chickpeas or other beans, blended with tahini, olive oil, lemon juice, salt and garlic. It is popular in the Middle East and in Middle Eastern cuisine around the world, however houmous can also be found in European retail. One downside, we’ve tested the microbial shelf life of houmous was limited to approximately 11 days.

We’ve performed studies to increase the microbial stability of a carrot houmous. After a thorough microbial analysis, we’ve found that yeast and mould count of untreated houmous increase in function of time and Total Plate Counts (TPC) exceeded the microbial limit on day 17. The growth of aerobic micro-organisms was completely suppressed by BactoCEASE NV Liquid as the TPC remained relatively stable. We’ve also detected visual changes with a phenomenon we call “bombage”, the appearance of gasses because of microbial spoilage.

Appearance and gas production in houmous treatments. Picture taken at day 29 of shelf life. From left to right: Untreated houmous and BactoCEASE NV Liquid treatment (2 %).

BactoCEASE NV Liquid buffered vinegar dosed at 2 % could effectively inhibit microbial growth in carrot houmous and extend the shelf life. Furthermore, the label friendly buffered vinegar solution did not affect the appearance. Even at the end of the study (day 21), microbial counts for the BactoCEASE NV Liquid treatment were still well below the microbial limit. This indicates that the shelf life could be extended with at least 10 days. Most likely BactoCEASE NV Liquid can extend the shelf life of houmous even longer.

Disclaimer:

Product allowance and labelling may differ based upon government requirements. Certain statements may not be applicable in all geographical regions.

Introducing Caroline Ecoffard - Product Platform Manager at Kemin

At your service during Covid-19 - a vlog from our team

Employee in the spotlight: Beate Boisten

Employee in the spotlight: Stef Moonen, QA/QC Specialist

Browse Latest Articles by Topic

- At your service during Covid-19 - a vlog from our team

- Interview with Prof. Frank Devlieghere – Food expert (part 2)

- Kemin’s label-friendly food solutions, powered by water solubility

- Food Safety and Shelf Life Solutions for Breakfast Trends

- Sensory Appeal Baked goods

- Interview Ines Colle

- Food Myths

- Glenn De Ceulaer talks NaturCEASE

- Interview Glenn De Ceulaer

- Enter the Organic Food Market with Kemin Solutions